Product Data - Floor Panel

MasterFormat 09 62 16

Description & Uses

Concreate Concrete Flooring:

Enjoy the contemporary look and durability of real concrete floors without the challenges of pouring and finishing a slab.

Concreate flooring planks, just ½-inch thick, have tongue and groove edges and ends to simplify installation and micro-beveled edges for ease of cleaning and visual appeal. Planks install quickly and cleanly with adhesives.

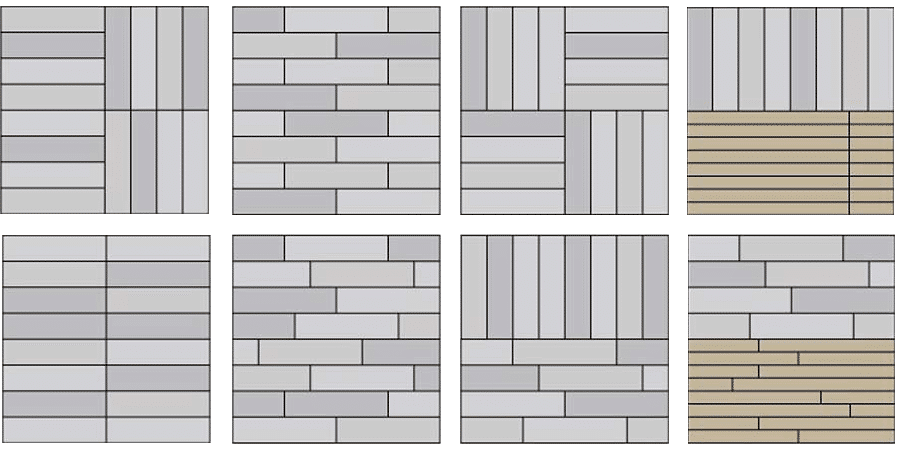

Use Concrete and Wood Together:

Concreate Floors can be installed with suitable wood floors as long as they have the same thickness, tongue and groove edges!

Physical Attributes

Composition

Base Layer: The 10 mm (3/8-inch) thick base layer is a specially formulated hydraulic cement mixed with recycled fibers. This cement requires only half the energy used to produce portland cement, reducing the CO2 emissions required to manufacture Concreate.

Top Layer: Concrete Floor: 4 mm (1/8-inch) thick proprietary blend of Portland cement, select fine aggregate, admixtures, recycled fibers, and fade-resistant pigments.

Testing Data

Attribute | Protocol | Performance | Comment |

Visual | |||

| Colorfastness | ISO 105-B02 | Grade 3-4 | |

| Response to Water | ASTM C1185 | • 20.6% Water Absorption • 0.05% Moisture Movement | |

| TChemical Resistance | EN 423 | Class 0 - No Affect • White vinegar • Isopropyl alcohol • Mineral oil • NaOH (5%) • Bleach (5.25% NaOCl) • Olive Oil • Red & white wine • Coffee & tea | Class 1- Very Slight • Hydrocloric acid (5% HCl) • Sulfuric acid (5% H2SO4) |

| Safety | |||

| Ignitability | EN ISO 9239-1 EN ISO 11925-02 | Class Bfl-s1 | |

| Slip Resistance | DIN 51130 | Mean overall acceptance angle (to horizontal) = 12.5° • Slip resistance assessment group = R1 | |

| ANSI A137.1 | Wet dynamic coefficient of friction (DCOF) = 0.31 average | ||

| EN 13983 | μ = 0.42 | ||

| Pendulum Test Value (PTV), Method AS 4663 | • 45 PTV before abrasion • 50 PTV after 500 abrasion cycles | Sustainable Slip Resistance after wear |

|

| Environmental | |||

| Volatile Organic Compound (VOC) | CDPH Method V1.1 | Compliant for schools and offices | CA Spec, 01350 |

| Formaldehyde | EN 717-1 | ND (Not Detectable) | |

| Impact Sound | EN ISO 717-2 | Impact Sound Improvement Index: ∆Lw = 14 dB |

Design Guide and Features

Wood

Floor

Above: Optional layout combinations of Concreate and compatible wood flooring!

Sustainability

Our products have been independently tested for conformance with environmental requirements for VOC & formaldehyde emissions, asbestos, lead and cadmium content.